Processors serving food or hygienic industries have varying degrees of compliance requirements for custom vessels solutions. The designation of "sanitary" has a wide range of definitions depending on the customer, the industry or the standard.

This video is a brief overview how Apache defines a base, mid, and high-level sanitary vessels.

Apache Stainless Equipment Corporation is a manufacturer of stainless equipment for a range of hygienic industries, including, food, beverage, biotechnology, pharmaceutical, cannabinoid, and life sciences.

A dedicated quality control and compliance team directs all tests, certificates and documents for all sanitary, ASME, and global standards.

ASME(美国机械工程师协会)是机械工程界中的代码和标准的领先开发商。ASME代码部分VIII详细信息有关船舶设计的强制性规则,包括工程,制造和压力容器的测试。这些标准提高了公共安全和健康,促进了质量和创新。以下是具有支持ASME测试要求的压力容器构造的主要参数。

<强>施工

诸如壁厚,材料和法兰等级等参数应用,包括压力,温度,腐蚀余量和流体流动。每段要求时,通过ASME检查员计算和审查/批准这些条件。不锈钢,Hastelloy,Al6xN,双链体和Inconel材料是ASME批准的压力容器施工材料在药物,生命科学和与健康有关的行业,其中apache有资格制作。

焊接

ASME标准也定义了质量,类型和完成焊接。头部样式(ASME F&D,80:10,2:1椭圆形),接缝,喷嘴,通道和其他组件都是由ASME代码设计的。 Applicable ASME Code welding procedures must be followed using certified ASME welders to maintain the structural integrity of an ASME pressure vessel. Welders must be certified to a qualified weld specification qualified per ASME code guidelines.

Safety Components

Gauges, valves, pressure outlets, and drainage are required safety components in ASME design pressure vessels. The proper selection of components and design is critically important to the safety and performance of the ASME vessel. The selection of safety components needs to be evaluated closely to define the required scope of supply.

Finishing

There is another ASME specification to ensure the quality and safety of parts used in pharmaceutical, bio-processing, and other industries requiring a hygienic vessel, called ASMP-BPE. BPE (Bio Processing Equipment Standard) specifies the surface finishes RA (roughness average) requirements and pickle passivation and electropolishing requirements.

Tests & Certification

There are significant testing, certifications, and documentation requirements for ASME compliance and satisfying the numerous customer requirements. Many require ASME inspection as well as a TOP (turnover packet). Some ASME testing and certification requirements include pneumatic, hydrostatic, liquid penetrant, saline, riboflavin, CIP coverage, material, base metal thickness, material trace, welder trace, Ferroxyl, PMI (Positive Material Identification) radiography, and UT.

Apache has been ASME certified for over 40 years. In addition to ASME, Apache is accredited in many other global standards. By setting parameters for quality and compliance, we offer greater value for our custom stainless ASME tanks and vessels.

作为大麻加工行业继续发展,增加法规遵循。通过进入市场的持续新产品和添加剂组合,产品的销售和分销将有更多的规定。CBD和Cannabidiol组分的加工和生产已经看到了越来越多的标准。

在搜索新的大麻处理或提取船舶设备供应商时,请问这五个问题:

Apache Stainless is a manufacturer of sanitary, highly engineered, ASME pressure vessels for a multitude of industries, including cannabis processing, pharmaceutical, health and biopharma. We have served the Cannabis and CBD processing industry several years with processing tanks, hydrocarbon extraction tanks, mixing tanks and separating vessels. We also design and manufacture vessels with Canadian Registration Numbers (CRN) for all Canadian provinces. We have all Stainless ASME certified manufacturing facility with custom capabilities including heat exchange surfaces, agitation, CIP (clean-in-place) componentry and controls. Apache has an in-house quality and compliance team to provide all testing and documentation requirements.

Visit Small Vessels for more information.

accrecitations 定制和压力容器制造商必须具有 ASME认证。符合国家锅炉和压力容器代码的遵守情况。压力容器制造商还必须制造给ASME材料规格,证书和焊接资格。 其他认证在制药,生命科学和卫生行业也至关重要。确认所有行业合规标准,包括: 质量保证与合规性 验证制造商有专用质量保证团队。所有全球认证计划都有显着的测试,认证和文档要求。内部检查服务对ASME项目有益。审查应包括的服务: The pressure vessel manufacturer must have expertise in the type of vessel and industry experience for the use of the vessel. Critical staff, fabricators, and welders must be ASME certified. All welders must be approved for the weld procedures required to make custom pressure vessels. Experience and reputation are also significant when developing relationships with inspectors, agencies, and governing officials to keep the compliance process moving forward smoothly. Service & Support Above all, assess the service and support provided by the manufacturer. The vessel manufacturer should be able to articulate technical discussions and be open and honest with timelines, cost, and compliance-related issues. Consider other research and questions, such as: • Is the proposal easy to understand and compare solutions?

•ASME UM

•ASME U

•FDA

•3-A

•CRN

•PED

•BPE

•气动测试

•静水测试

•液体渗透剂(染料渗透剂)测试

•盐水测试和证书

•Riboflavin / CIP(干净的)覆盖测试

•材料测试报告

•基础金属厚度证书

•材料迹线•焊工追踪

•铬铁检验和证书

·正材料识别(PMI)和证书•铁氧体水平和证书

•射线照相和分析

•UT焊接测试和证书

•翻页包(顶部) required

Experience

• Do you have direct access to the engineer for questions?

• Does the company provide timely and accurate documentation?

• Does the company offer after-market parts and field service?

在发生意外事故时,如工具掉进油箱造成损坏;表面划痕和凹痕通常可以现场修复,只要它们不超过最低要求,通过机械抛光或手工/棒电解抛光。搅拌器性能下降或失效往往是由于部件磨损、装配不当或轴弯曲或断裂。根据情况、停机时间和故障的严重程度,可以与搅拌器制造商或容器制造商联系维修搅拌器。当对储罐或容器中的压力下降进行故障排除时,典型的原因往往与密封有关。密封失效的一个标志是产品从密封中出来。帮助减少意外密封泄漏发生的频率,建议使用一个好的密封维修计划来解决很多压力/性能问题,如:< br / >•密封替代一直被忽视的< br / >•平斑点海豹是替换的符号< br / >•不当或不正确的海豹出口< br / >•缺口,最好的做法是避免产品浪费,关键的停机时间是为所有销售点库存密封,并在预防性维护计划中管理密封。

需要注意的是,任何对容器ASME压力区域的焊接修复,都需要一个R-Stamp。r型印章是美国锅炉和压力容器国家委员会在修理ASME水箱或容器时所要求的认证。

根据船的大小和修理类型,Apache的服务技术可能会进行现场修理,或者在某些情况下,坦克被运回工厂。 Apache can provide services including:

• Field service and troubleshooting to all types of stainless and high alloy tanks

• ASME / National Board R-Stamp repair and modifications

• Surface finish repairs

• Non-code repairs and modifications including piping and heat transfer jackets

• Seal and agitation repairs and modifications

• Accessory repairs

• Head and tank shell repairs

• Leak detection

• Audit and service contract available

Emerging life sciences, and health and wellness product manufacturers must carefully plan budget and start-up costs to launch their products. Many of these entrepreneurs begin production with a general use vessel.

A stainless general use vessel has a lower entry price. Depending on the process and the demand for the product, general-use vessels may serve a small manufacturer very well for many years. Dispensing and storage vessels, vacuum and low-pressure vessels are common examples of general use applications.

However, when demand outpaces production, the manufacturer may require a vessel that is customized for the processing needs. Here is a case story of a manufacturer that switched from a general use to a custom ASME pressure vessel:

BEFORE: A fast-growing botanical extraction processor was unable to produce the quantity of product needed to fulfill demand. Their process involved an imported general use vessel that was placed in a rudimentary ice bath for temperature control. This process resulted in waste of non-consistent product and constant staffing and manual intervention to monitor and adjust.

AFTER: Apache's small vessel team provided an ASME processing vessel that completely replaced their batch process. The new vessel was designed with a thermal heat jacket that heated and cooled the product to the exact temperature required for the extraction process. The ASME vessel was jacketed with tri-clamp ferrules and included a site glass and high-pressure sanitary fittings. The vessel has a pickle passivated finish that provides ease of sanitation between batches.

While the price point for a custom manufactured vessel was higher than a general use tank, the ability to quadruple production off-set the cost of the vessel and resulted in a quick return on investment. Apache's custom vessel runs continuously day and night; it eliminated product waste and removed employee monitoring and intervention.

Visit standard vessels or visit custom ASME vessels, for more information!

用于制造商业原始设备的钢材必须符合最终用户的性能、价格、交货期和质量要求。工业设备供应商,如Apache,必须利用与工厂和合作供应商的关系来管理不断变化的市场。阿帕奇不锈钢材料采购计划的一部分,重点是与优质的国内和国外供应商合作。

不锈钢板和板材是在美国生产的,这是阿帕奇的坦克,容器和食品加工设备的主要基础材料。此外,大多数哈氏合金和其他高合金性能的金属材料是在美国制造的。另一方面,管道和配件主要来自国外供应商,因为国内没有足够的需求。根据政治气候的不同,进口关税会影响从中国和其他国家进口钢铁材料的成本和可得性。一些行业需要来自国外市场的产品,这些产品可能是特定的薄片、尺寸和材料类型,但这些行业将为此支付额外的费用,并可能需要延长交货时间。作为一个不锈钢的重要用户的好处之一是与不锈钢生产商和分销商的关系。阿帕奇的钢铁供应商将一部分钢材分配给阿帕奇,后者提供的供应交易相对较短。 When we have a line on repetitive need, we initiate inventory strategies to keep our supply as fluid as possible. Many other components and materials are affected by timing and supply; Apache understands lead times and availability and also leverages relationships to manage delivery to provide the best timing possible.

Our suppliers understand our needs and hold a higher level of steel quality. The relationship and partnership with our steel vendors has strengthened our expectations, with some partnerships lasting up to 45 years when Apache was founded.

Apache uses more than 2000 tons of stainless and high alloy per year. We are in the business of heavy gauge commercial manufacturing of custom equipment for high-compliance industries. Our ability to manage domestic and foreign material as well as price, timing and quality of all material and components is resolved for serving over 100 industries represented by our industrial and commercial processing customers.

为了帮助我们的储罐和容器客户了解夹套容器和热交换表面,Apache分享了内部专家制作的这本电子书,“ASME容器传热表面的摘要和属性”。

夹套容器在许多工业中使用,可以去除升高的反应热(加热反应堆容器)或降低高粘性流体的粘度。基本上有三种类型的外夹套传热表面:常规夹套、半管夹套和凹陷夹套,它们焊接在容器的外部。内部线圈也可以作为独立选项使用,也可以与其他类型的外部护套结合使用。

质量保证的一个重要部分是制造船只和完成满足ASME合规性所需的认证;同样重要的是,从项目工程经理到采购团队的所有各方都要了解这些流程和程序。

Apache的质量专家已经收集了一份关于工厂测试和ASME储罐和容器认证的信息资源。与客户了解与测试和文档要求有关的内容是很重要的。

重点包括:

工厂测试回顾

需要报告的制造过程

认证概述

顶部(移交包)文档包

brakebush Brothers,一家领先的鸡肉产品加工商,与阿帕奇不锈钢设备公司合作,为其威斯康星州Westfield工厂设计、制造并交付一个新的20000加仑的新鲜油箱。

Brakebush公共事业部经理David Meyer需要一个新的储罐来满足生产需求,因此选择了Apache不锈钢公司;作为优质不锈钢水箱制造商的声誉,以及在传热表面和卫生水箱表面处理方面的专业知识 ;第13条;6&rdquo;储罐直径为33&rsquo;英尺高,替换了一个8000加仑的油箱,该油箱将搬迁到另一个Brakebush工厂。

Apache的销售经理David Foulkes曾与Brakebush和Apache合作;s储罐团队将为新储罐提供规范,包括安全壳、蒸汽凹形夹套、隔热层和保护罩,以及监控和调整油的热温度的控制装置,特别是在威斯康辛州的冬季,以及进入工厂进行生产操作所需的流量

威斯康星州布拉克布什韦斯特菲尔德工厂拥有超过500000平方英尺的生产设施,拥有最先进的烹饪操作。Westfield也是Brakebush的公司办公室。

阿帕奇不锈钢公司位于威斯康星州比弗大坝,为北美各地的商业制造商提供服务。阿帕奇坦克被发现在食品和饮料加工设施,在燃料精炼厂,乙醇厂,化学工业,生物技术和制药公司和保健和美容产品制造厂

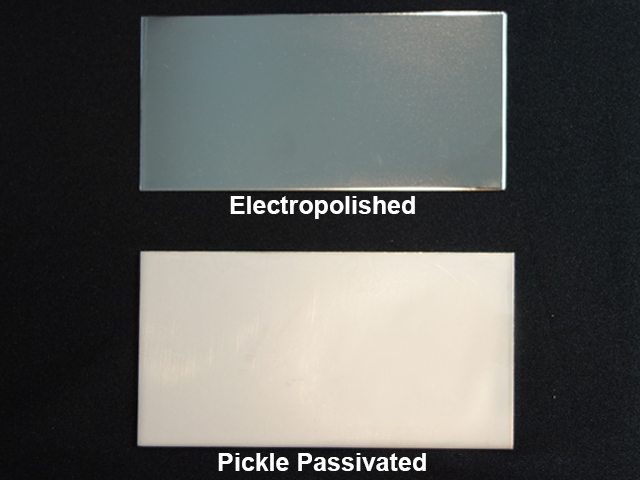

The main difference between pickle passivation and electropolishing is the appearance and RA (roughness average) of the stainless material. In the photo, an electropolished sample is shown above a pickle passivated sample. The pickle passivated sample has a white appearance, while the electropolished sample has a mirror-like, shiny finish.

Pickle Passivation is the immersion of metal in a pickling bath such as nitric-hydroflouric acid. The process removes metal such as impurities and heat marks from welds.

Electropolishing is an electro-chemical process that removes surface material from stainless steel. The process typically starts with an immersion of the component into a controlled bath of electrolyte that is charged with a DC power supply. Apache’s RA tests show improvements up to 50% smoother, depending on the material.

Do you have more questions like this one?

Check out the Contract Manufacturing FAQs page.